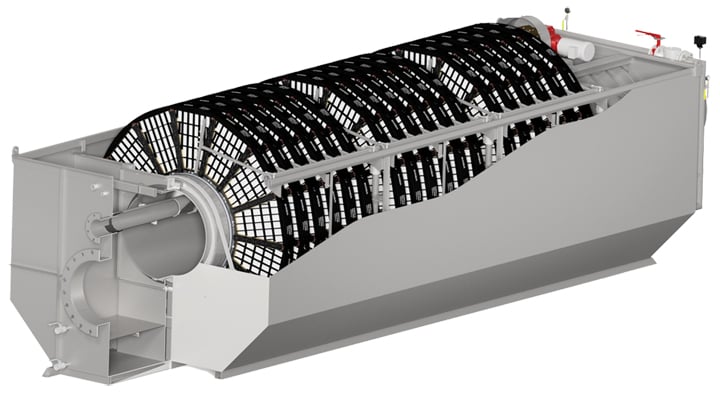

Forty-X® Disc Filters

See All Disc FiltersHigh-quality, high-volume filtration in less space

- is the minimum order quantity for this product. Please check quantity and add to cart again.

- More cost-effective solution than traditional sand filters.

- Low backwash generation resulting in higher efficiencies.

- Design simplification when compared to competition, fewer moving parts with no need to oscillate the spray header.

- 316L stainless steel filtration media much more robust than polyester options

- Pressure assisted panel gasket sealing allows for zero leakage around filter panel.

- View Gallery

High-quality, high-volume filtration in less space

- More cost-effective solution than traditional sand filters.

- Low backwash generation resulting in higher efficiencies.

- Design simplification when compared to competition, fewer moving parts with no need to oscillate the spray header.

- 316L stainless steel filtration media much more robust than polyester options

- Pressure assisted panel gasket sealing allows for zero leakage around filter panel.

Description

The Forty-X® Disc Filter is a high-rate tertiary filter that utilizes an optimized tertiary mesh (OTM) filter panel woven from 316L stainless steel threads to create a weave that improves solids collection and rejection.

The panel configuration includes a robust, molded structural frame and a pressure-assisted seal allowing the panels to sustain and operate at a higher head loss and providing higher throughput when compared to other woven polyester, flat panel disc filter designs. Our filter panels are also housed in a trash tolerant filter panel housing, which assures the unhindered flow of water between panels and rejects plastics, algae clumps or other floatables.

The inside-out filtration design of the Forty-X Disc Filter allows the water to flow into an influent center drum and then out through the disc filters capturing solids on the inside surface of the media. This filtration characteristic eliminates the need for a separate system for handling floating material and settling sludge. The captured solids are also backwashed into a reject trough using a positive pressure spray cleaning system. A backwash cycle is automatically initiated by a level sensor in the influent channel with filtration continuing during backwash. The modular design offers flexibility for a broad range of flows and

applications including municipal tertiary filtration, water reuse and

process water filtration.

Patents

May be covered by one or more of the following patents:

7,597,805; 7,972,508; 8,118,175; 8,409,436; 8,801,929; 8,808,542; 8,961,785

Features

Features

- Small footprint

- Innovative panel design providing more filtration throughput per disc

- Woven optimum tertiary mesh (OTM) filter panel utilizes 316L stainless steel threads with higher porosity.

- Modular design - flexible and expandable.

- Wind safe stainless steel sliding arch covers for easy access and maintenance.

- Suitable for retrofit for some existing conventional filters due to matching hydraulic footprint.

- Less frequent backwash cycles resulting in energy reduction.

- Superior solids capture and holding capacity.

- Title 22 approved

Documentation

Maintaining Forty-X™ Disc Filter Backwash Spray Nozzles

Maintaining backwash spray nozzles is critical to ensure proper backwash cleaning operation and performance of your tertiary filtration system. Watch this short video to see a step-by-step process on how to clean and maintain your spray nozzles!

Watch now