Proper disinfection and filtration of an aquaculture system provides benefits to the facility and their fish. Treating aquaculture water systems is crucial to each phase of the production process. Aquaculture water quality impacts the success of fish farmers, fisheries, manufacturers, and distributors. Every aquaculture facility should invest in their water treatment system to achieve compliance, improve profits, or produce a higher-quality product.

Benefits of Improved Aquaculture Water Quality:

Fish produced with treated water are proven to grow faster and be less prone to disease. This creates a higher-quality end product for the farm's consumer. The aquaculture facility itself also benefits from having properly treated water. Improved water quality leads to simplified operations and less maintenance long-term. Additionally, the facility improves their sustainability efforts by delivering a high performance in a small footprint.

Aquaculture Applications

Land-based Recirculating Aquaculture Systems (RAS)

RAS are used for fish production where water exchange is limited and the use of biofiltration is required to reduce ammonia toxicity. Other types of filtration and environmental control are often also necessary to maintain clean water and provide a suitable habitat for fish. The main benefit of RAS is the ability to reduce the need for fresh, clean water while still maintaining a healthy environment for fish. With up to 95% of the water in a RAS operation recycled, water quality is crucial to ensure optimal conditions and that the lives of hundreds of thousands of fish are not at stake.

Fish Hatcheries

A fish hatchery is a place for artificial breeding, hatching, and rearing through the early life stages of finfish and shellfish in particular. Hatcheries produce larval and juvenile fish, shellfish, and crustaceans, primarily to support the aquaculture industry where they are transferred to on-growing systems, such as fish farms, to reach harvest size.

Well and Processing Boats

A well-boat is a fishing vessel with a well or tank for the storage and transport of live fish. Contemporary well-boats can be used to transport live smolt to sea, to bring them from aquaculture sites for processing, and to sort and delouse fish.

When using well boats for transporting live fish, the wells must be hygienic, and the transport water changed regularly. By treating the transport water with UV, pathogens are inactivated, reducing the risk of infection to cargo or the environment. Our ozone generators provide the ozone required for the disinfection of the fish systems, tanks and pipework, keeping them hygienic, clean and ready to receive the next batch.

Shellfish Depuration

Depuration of seafood is the process by which marine or freshwater animals are placed into a clean water environment for a period of time to allow purging of biological contaminants (such as Escherichia coli) and physical impurities (such as sand and silt). The most common subjects of depuration are such bivalves as oysters, clams, and mussels.

Our Aquaculture Treatment Solutions:

Evoqua has been working alongside the aquaculture industry for decades. From fish farmers and manufacturers to integrators and well boat manufacturers, we understand the challenges facing the aquaculture industry.

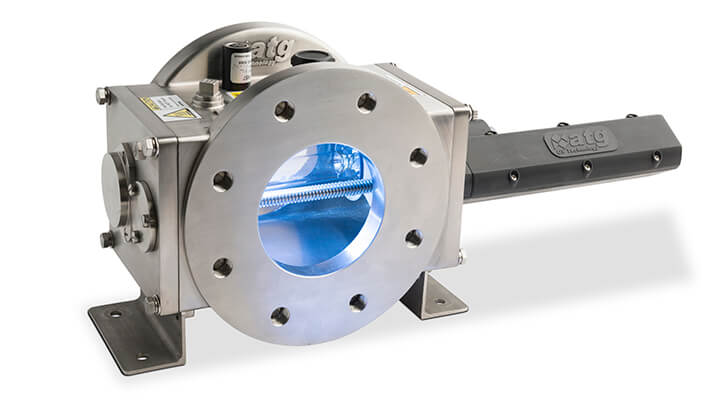

We design, manufacture, and maintain a wide range of disinfection and filtration systems for every aquaculture application, including land-based recirculating aquaculture systems (RAS), flow-through systems, well-boats, and shellfish depuration.

Evoqua is one of the leading global providers of disinfection and filtration solutions. Our water management engineers and aquaculture experts can advise how best to improve your water quality, improve fish health, increase stock density, and boost yields by supporting the full range of disinfection systems (Ozone and UV) as well as industrial screen and media filtration solutions.