First settled in 1836, the City of Berea, Ohio gained acclaim as being the source for dimensioned stone formed from locally quarried sandstone, notably grindstones. The grindstones were shipped to Cleveland by oxcart and, as demand grew, later by a purpose-built railroad to the Big Four Railroad across the Midwest. Now many of the former quarry pits are better known as Baldwin Lake, Wallace Lake and Coe Lake.

Challenge

The City of Berea public water system, provides service to approximately 20,000 people, using surface water drawn from the East Branch of the Rocky River; however, supplies can also be drawn from nearby Coe Lake and Baldwin Creek as needed. As open surface water sources, they are vulnerable to run off and other forms of contamination. The City mandates the best possible water quality for its residents and had been closely monitoring the quality of the water source. In 2008, Cryptosporidium was detected in 10 of the 24 samples collected from the East Branch of the Rocky River.

This emerging threat to public health is effectively deactivated using UV, and has now become an important barrier both in the U.S. and globally to ensure that drinking water is healthy and free from any harmful organisms. Nationwide UV systems are being installed into municipal drinking water facilities to deactivate Cryptosporidium and Giardia, both organisms that are tolerant to chlorine.

Solution

Stantec Engineering was retained by the City to oversee the selection of the UV manufacturer to ensure reliability, regulatory compliance, ease of use, and value for the City of Berea. This facility will became one of the first in Ohio to seek regulatory credit for the use of UV to deactivate the Cryptosporidium oocysts.

To assist with ongoing water quality improvements and to maintain a state of the art water treatment process, the City of Berea had initially installed Granular Activated Carbon (GAC) filters to their Dr. Dimiter Ramandanoff Water Treatment Plant. The GAC system provides high quality water filtration, eliminating periodic taste and odor events from the water. An 800,000 gallon, above-ground tank was added to ensure continuity of service when the older 1 million gallon tank was being serviced for maintenance and cleaning.

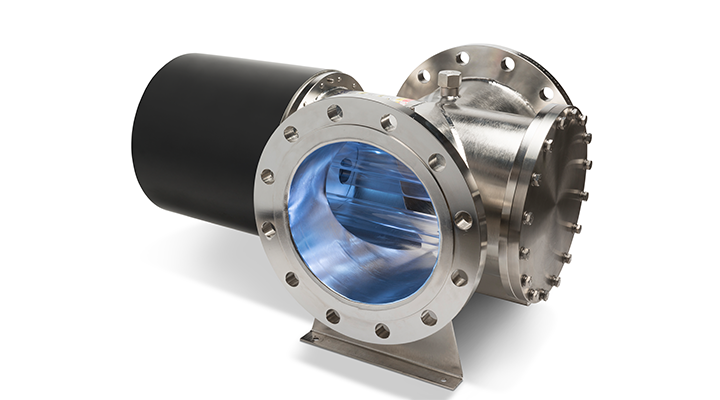

The ETS-UV™ systems were selected after an evaluation of leading UV suppliers. Two ETS-UV SX-425-10 validated systems were installed. Typically, a duty and standby arrangement is required, to ensure that an adequate level of treatment is always achieved. An online transmittance monitor measures the transmittance of the water, and a record of this important parameter is maintained. The water plant operators already kept detailed records of the water quality. They are now required to maintain a record of the performance of the UV system to ensure public safety. Each of the UV systems contains a number of medium pressure UV lamps, automatic wiping systems, and UV intensity monitors. A flow meter signal is provided by the facility to the ETS-UV control panels, and the system control panel is able to alter the power to each lamp to make sure that the correct UV dose is always delivered to the water. Naturally occurring iron, manganese, and organics cause fouling of the quartz sleeves. The ETS-UV automatic wiping system keeps the quartz clean and free from fouling.

Results

" We’ve been impressed so far with the quality of manufacturing of the ETS-UV systems, their responsiveness and particularly their knowledgeable technical staff. It is important that we maintain the highest quality water from our facility, and the ETS-UV system will supplement our conventional disinfection process. Our facility is a state-of-the-art water treatment facility, and we are proud to disinfect water using UV light to get disinfection credits for deactivating Cryptosporidium. "