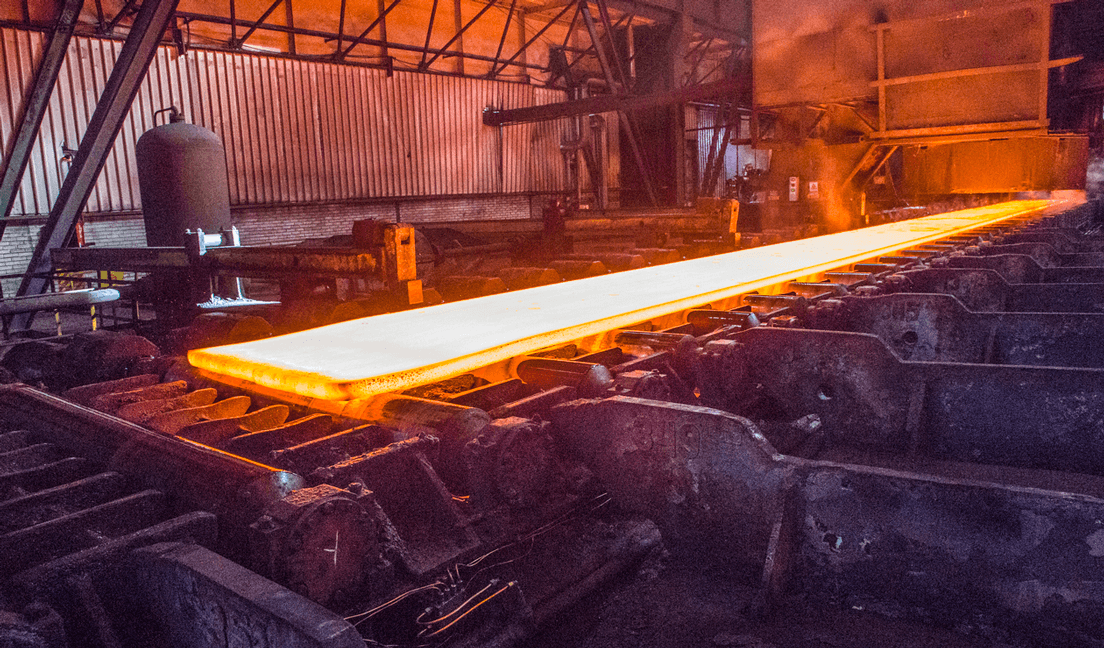

In industrial applications, water used in processing, cleaning, and emission controls may result in both water and solids that may be contaminated. Contaminants include metals, phosphates, the newly PFAS or other toxins. These require removal or treatment before discharge or reuse. Once the sludge has been dewatered, both the solid and liquid component may be treated independently.

Dewatering does not treat water instead it separates liquids and solids so they are able to be treated

Separating Solid and Liquid Components

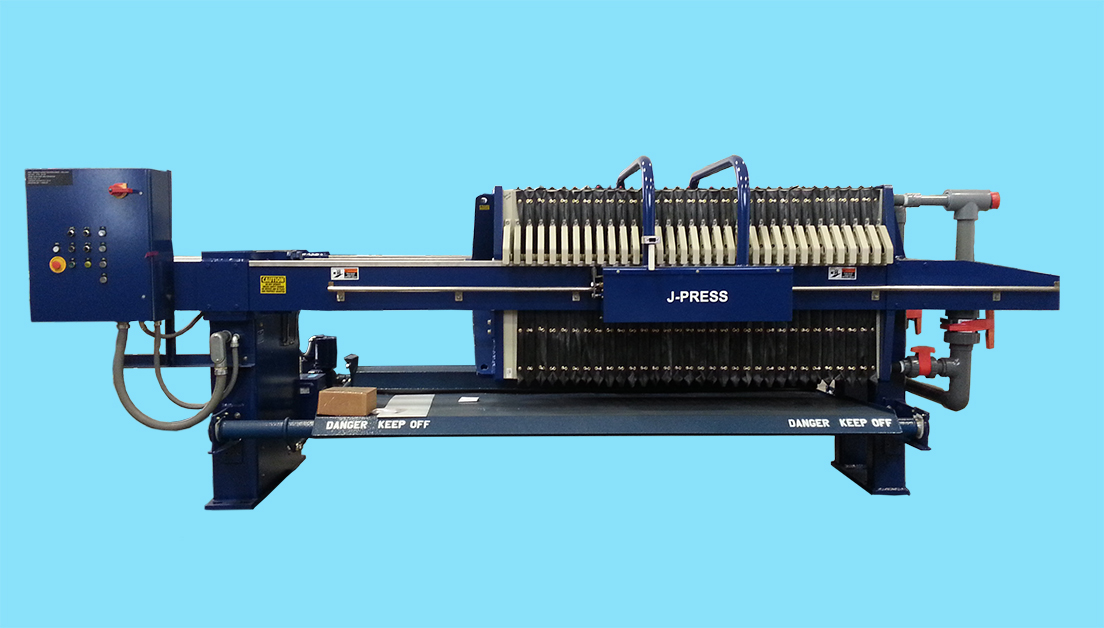

Sludge dewatering separates sludge into liquid and solid components for waste minimization to achieve overall cost efficiency for disposal. Dewatering is not necessarily intended to treat the sludge or liquid, but instead to separate the solid and liquid components so that it is easier and more cost-effective to handle the separated phases for final disposal. Sludge dewatering is typically focused on reducing the weight and volume of the sludge so that solids disposal costs - including transportation - are kept to a minimum.

The choice of sludge dewatering treatment is dependent on several factors including the characteristics, volume, timing and the available disposal options. In most industrial applications, a dry filter cake produced by a filter press is the desired product and can either be virgin or recycled before being sent for further processing. In some cases, a rotary press or dryer may be the better option.