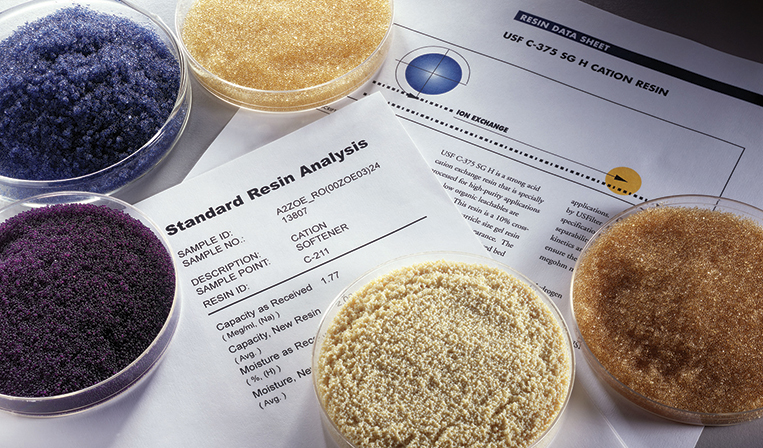

Ion exchange resins are used in multiple systems in nuclear power plants to remove specific contaminants. The individual chemistry demands of each system is used to determine the best resin. Evoqua provides ion exchange resins processed to conform to each nuclear plant's individiual specifications.

We work with each plant's chemistry departments to match products that help meet a specific system's performance goals.

Resins are used in various nuclear power plant locations including the Advanced Liquid Processing System and Condensate Polishers. These resins found in the plant’s steam cycle, primarily remove dissolved contaminants to create ultrapure water for reuse. The primary resin used in this application is a mixed bed containing both anion and cation resins. The cation resin, for example, is normally a high capacity, highly crosslinked resin such as the C-471C H or the C-661C H.

Cations, anions, and mixed beds are the types of resins used. Different forms of resins – borated resins, lithiated resins and other specialty forms.

Nuclear plant systems that use ion exchange resins:

- Advanced Liquid Processing System (ALPS) – removes radioactive materials from contaminated water

- Chemical and Volume Control System (CVCS) – cleans part of the Reactor Coolant System and helps to maintain boron concentration

- Condensate Polishers – removes dissolved contaminants to create ultrapure water

- Deborating Beds – boron reduction

- Fuel Pool Demineralizers – removes contaminants in the fuel pool

- Lithium Removal Beds – lithium removal

- Radwaste Demineralizers – removes contaminants from radioactive water in the radwaste system

- Reactor Water Cleanup – maintains reactor water quality

- Stator Cooling - cleans water used to keep the copper stator bars cool

- Steam Generator Blowdown – cleans water removed from the plant’s steam cycle

Check here for specific information related to powdered resins by Epicor.