Wastewater typically contains a large amount of nutrients - particularly phosphorus - that can pose a harmful threat to infrastructure and the environment, causing problems such as eutrophication in waterbodies and a buildup of struvite in mechanical systems.

To remove it from wastewater it must be converted to a solid form and then separated from the liquid which can be accomplished chemically or biologically. When recovered, wastewater treatment plants can improve effluent quality, meet stringent discharge limits, and convert discarded phosphorus into an environmentally friendly fertilizer needed to grow food.

Phosphorus Management Can Help Contribute to a Future Circular Economy

Proven Solutions for Phosphorus Mitigation

Evoqua works closely with consulting engineers and municipalities and understands phosphorus removal challenges. We have a comprehensive product portfolio and experienced professionals to help provide best options for new treatment plants, retrofits, upgrades, or sustainable nutrient recovery applications.

Our innovative BioMag® and CoMag® ballasted clarification systems use magnetite - fully inert iron ore particles - to ballast biological floc or conventional chemical floc, enhancing settling rates and increasing the performance of wastewater and water treatment facilities, while substantially reducing costs.

Evoqua's Aerobic Wastewater Treatment technologies can help enhance biological phosphorus removal (EBPR) without the addition of chemicals providing a sustainabile solution.

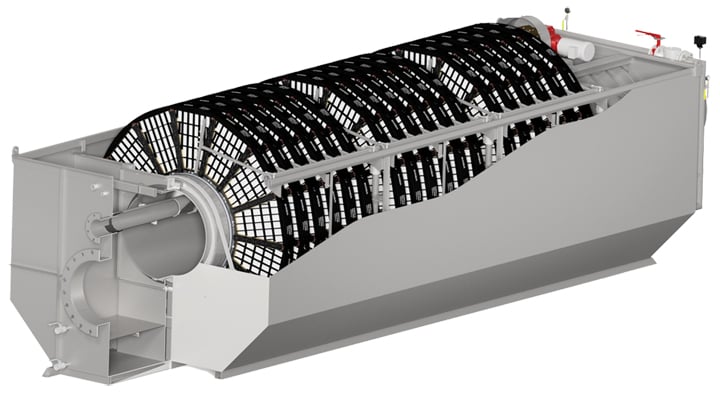

Our Forty-X™ Disc Filtration systems provide a solution to meet low level phosphorus effluent requirements by removing particulate associated with phosphorus. Chemicals may also be added to precipitate soluble phosphorus to improve removal.

Ostara's Nutrient Recovery Solution from Evoqua turns phosphorus challenges into opportunities. Recovering phosphorus lowers the impact on local waterways through reducing effuent levels and producing a high value fertilizer that reduces nutrient runoff.