Evoqua, now together with Xylem, have been a proud provider of disinfection solutions for municipal wastewater for more than 100 years. We maintain a strong commitment to solving water treatment challenges faced by customers, by offering a wide range of solutions to suit any municipal application. With the right disinfection solutions in place, you can:

- Optimize your performance

- Reduce OPEX and CAPEX

- Inactivate pathogens and remove contaminants

- Meet sustainability objectives

- And more!

Our full range of disinfection-associated technologies include analyzers and process controllers, ultraviolet disinfection systems, hypochlorite generation systems, gas feed systems, chlorine dioxide generation equipment, and more. See below for the many ways in which these technologies can be applied into your wastewater treatment facility.

Disinfection Solutions For Municipal Wastewater Applications:

|

|

|

|

|

||

|---|---|---|---|---|---|

| Application | UV | OSEC® Systems | W&T® Gas Feed Systems | Chlorine Dioxide | Analyzers & Controllers |

| Wastewater (Stream Discharge) |

• |

• |

• |

• |

• |

| Water Re-Use |

• |

• |

• |

• |

|

| Utility Water (Plant Service Water) |

• |

• |

• |

• |

• |

| Combined Sewer Overflows (CSO) |

• |

• |

• |

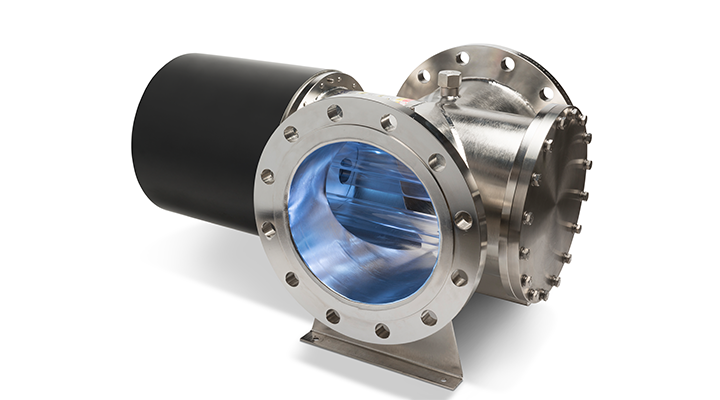

Spotlight on UV Disinfection Systems

UV is a proven, safe, and reliable method of disinfection for municipal wastewater and reuse water. The highly efficient and sustainable process does not involve the use of added treatment chemicals and reduces the risk of disinfection by-products by lowering chemical disinfection requirements. It is effective as both a primary and secondary barrier disinfectant. UV is also widely used as part of a multi-barrier treatment strategy, used as the primary disinfectant, followed by the addition of residual chlorine to protect the treated water throughout the distribution network.

UV System Advantages

- Proven solution against pathogens

- Safe and easy to operate technology

- Easy to install and retrofit into existing plants

- Highly efficient technology reduces CAPEX

- Simple and low maintenance technology reduces OPEX

- Independent 3rd party validated performance to USEPA UVDGM where applicable

Spotlight on OSEC® On-Site Hypochlorite Generation Systems

OSEC systems safely generate sodium hypochlorite on-demand, using only salt, water and power. With over 30 years of history installing systems throughout the world, our branded OSEC system is suited to many applications across municipal markets.

OSEC System Advantages

- Safe and sustainable method of producing chlorine on-site

- Easy to use systems that are highly reliable in operation, simplifying your disinfection

- Significantly lowers operating costs and increases safety when compared to using purchased bulk hypochlorite

- No handling of dangerous chemicals: consumes salt, water and electricity

- Storage of a low quantity of disinfectant for economic production according to demand

- Increases plant security and independence

- Cost savings can be achieved via off-peak production scheduling

Spotlight on Gas Feed Systems

Chlorine is a highly effective oxidant and a relatively economical option for disinfection. Chlorine can be safely transported, easily applied, measured, and controlled. All vacuum operated gas feed equipment & solutions for simple & reliable disinfection dosing, control & safety management. There are numerous applications in municipal or industrial water treatment, the disinfection of potable and swimming pool water, the treatment of cooling water and industrial wastes, and much more. Some typical wastewater related applications for gas feed include: Cooling Towers. Potable Water, Utility Water, Water Reuse, Wastewater, and more.

Gas Feed Advantages

- Differentially regulated technology

- Safe, simple and reliable disinfection: chlorination and dechlorination

- Accurate and reliable all-vacuum dosing

- Destroys a broad range of microorganisms

- Scalability and low cost

- Elemental Cl2 does not degrade and remains at a consistent concentration under pressurized cylinders

Spotlight on Analyzers & Controllers

For municipal applications, monitoring and control systems are critical to ensure the highest water quality, compliance and safety. As well as support with reducing costs and minimizing maintenance to help with tightly controlled budgets. Delivering higher levels of accuracy in measurement and dosing for water treatment is vital to meeting regulatory requirements for today and tomorrow, as well as reducing spend on chemicals for disinfection.

The Xylem/Evoqua Advantage

- Simple set-up and data management for complete control of water quality

- Seamless integration into existing systems

- Compliance-focused support to meet disinfection regulations

- Minimize chemical overdosing risks

- Enables quick identification of quality issues

- Modern communication options such as Ethernet (HTTP Protocol and Modbus® TCP) and RS 485 interface

- Fast response time to meet fluctuating disinfection demands

Spotlight on Chlorine Dioxide

Delivering safe, consistent, high-purity chlorine dioxide for disinfection and peroxidation. Chlorine Dioxide is a highly effective disinfectant and oxidizing agent that offers many clear advantages to ensure a clean and safe water supply. It helps to destroy waterborne pathogens, parasites and microorganisms in biofilms (prevention of Legionella and pseudomonas), control taste and odor, and is used for the oxidation of iron and manganese, as well as control of algae growth.

The Xylem/Evoqua Advantage

- More effective against planktonic bacteria and biofilms

- Effective at a very low dose rate

- Stable disinfection over a wide pH range

- Reliable and safe generation system

- Lower reactivity with natural organic matter than chlorine

At Xylem, we offer solutions to meet nearly any disinfection need, large or small, and have an experienced sales and customer support team to help address any challenge. When you purchase solutions from Xylem or one of our trusted channel partners, you are entering into an on-going relationship with our team of specialists who understand your process and your productivity goals—even as they evolve over time. Our years of experience and in-depth expertise are at the core of our success.

Contact us today to learn how we can help you optimize your wastewater treatment operations.

NOTES

Evoqua UV disinfection generator systems undergo third-party validation testing in accordance with the UVDGM (USEPA, 2006). Validated products are tested to confirm a minimum inactivation equivalent of 3 log (99.9%) for microorganisms in accordance with NSF/ANSI 50 and the UVDGM. Performance is not claimed nor implied for any product not yet validated; unvalidated products use single point summation calculations to provide delivered dose recommendations. Performance limitations depend on feed conditions, overall installed system design, and operation and maintenance processes; please refer to Operations Manuals. For more information: Contactus@evoqua.com

Evoqua OSEC® systems are designed to produce 0.65-1% sodium hypochlorite under normal operating conditions. With less than one minute of contact time, the OSEC system produced concentration range (6,500-10,000ppm) is significantly higher than the concentration requirements to meet industry standards for microorganism inactivation and disinfection. Specific disinfection rates depends on dose, concentration and time (CT value), pH, and water temperature. Performance limitations depend on feed conditions, overall installed system design, and operation and maintenance processes; please refer to Operations Manuals. For more information: Contactus@evoqua.com

s is a trademark of Schneider Electric.

Evoqua’s Chlorine Dioxide Generation systems make no claim regarding disinfection. These systems apply EPA-registered chlorine dioxide precursor chemicals, for which the generation of chlorine dioxide used as a disinfectant for microbial control in water is presented on the labels’ directions for use. Performance limitations depend on feed conditions, overall installed system design, and operation and maintenance processes; please refer to Operations Manuals. For more information: Contactus@evoqua.com

Evoqua’s Gas Feed systems make no claim regarding disinfection. These systems apply EPA-registered pesticides (e.g., chlorine) which may be used as a disinfectant for microbial control in water, which is presented on the labels’ directions for use. Performance limitations depend on feed conditions, overall installed system design, and operation and maintenance processes; please refer to Operations Manuals. For more information: Contactus@evoqua.com

Modbus is a trademark of Schneider Electric.