Many industrial wastewaters contain dissolved metals as a result of materials and chemicals used in the manufacturing processes. In response to concerns for the overall health of the environment, regulatory bodies across the world continue to decrease the allowed discharge limits for many regulated contaminants such as mercury, lead, cadmium, nickel, zinc, copper, chromium, arsenic, and selenium. As a result of these decreasing limits, many existing technologies used to polish industrial wastewater can no longer achieve the standards required in discharge permit limits.

Metals removal is a process used to reclaim metals for refining or recycling. As regulations for heavy metal effluent limits become stricter, metal removal processes used to reclaim metals for refining or recycling is an important step in the wastewater treatment process to keep contaminants from reaching groundwater supplies.

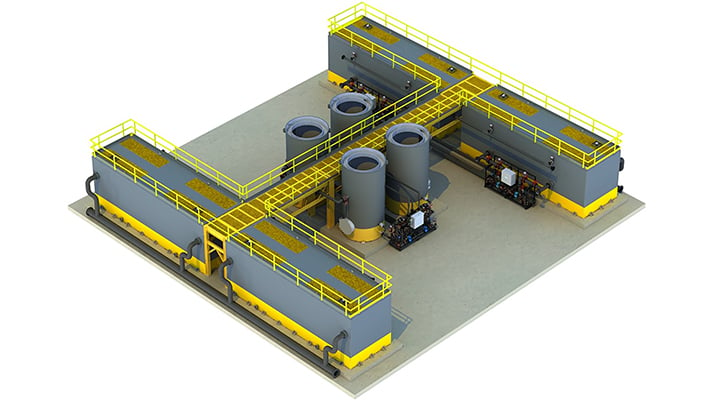

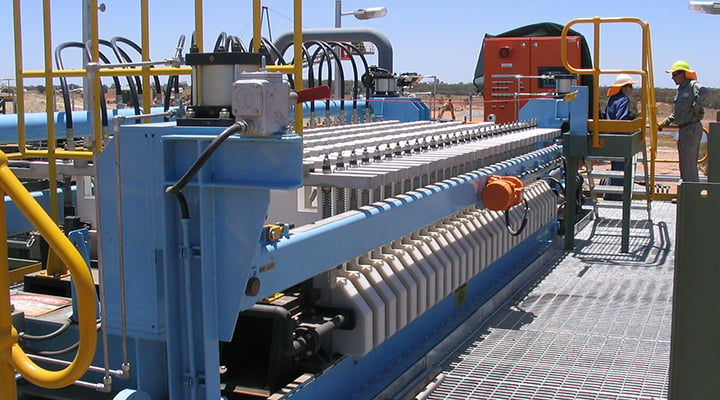

Evoqua offers equipment to precipitate and separate metals in all steps of the process with a wide range of filter press capacities to provide the mining industry with a cost-effective solution for mineral concentration removal.

The Metals Removal Process

The metals removal process can be utilized to claim metals for refining or recycling. It is also an important process in wastewater streams to keep contaminants from reaching groundwater resources. Evoqua has equipment to precipitate and separate metals in all steps of the process with the J-Press® Filter Press an ideal cost-effective solution for the mining industry.

During the process, after frothing or floating has taken place, the floating metal is sent to a clarifier where settling occurs and then sent to the filter press for dewatering before being sent to a smelter. Evoqua offers s a wide range of filter press capacities to supply the mining industry with a cost effective mineral concentration.

Waste flow is sent to chemical reaction chambers, where neutralization and precipitation occurs by adjusting pH and adding reagents. Flocculation is performed by adding coagulants and/or polymer. The flocculant is settled out in a clarifier. Settled sludge is transferred to a thickening tank, where it may require chemical conditioning, and eventually pumped through a J-Press® filter press for dewatering.